Hot water cylinder repairs address issues like low pressure, malfunctioning heating elements, leaks, and corrosion. Early detection through regular inspections is key. DIY repairs require knowledge; complex issues need professional technicians. Focus on temperature control mechanisms, insulation, and tank health for effective troubleshooting. Regular maintenance prevents severe damage and ensures efficient hot water cylinder operation.

Diagnosing hot water cylinder problems is essential for efficient heating and potential cost savings. This guide outlines a step-by-step process to identify common issues, ensuring optimal performance. From checking for leaks and corrosion to evaluating heater element health and inspecting insulation, each section provides crucial insights into hot water cylinder repair. By following these steps, you can effectively navigate and resolve potential problems, extending the life of your hot water cylinder.

- Identify Common Hot Water Cylinder Issues

- Check for Leaks and Corrosion

- Evaluate Heater Element Performance

- Assess Temperature Control Mechanisms

- Inspect Insulation and Storage Tank Condition

Identify Common Hot Water Cylinder Issues

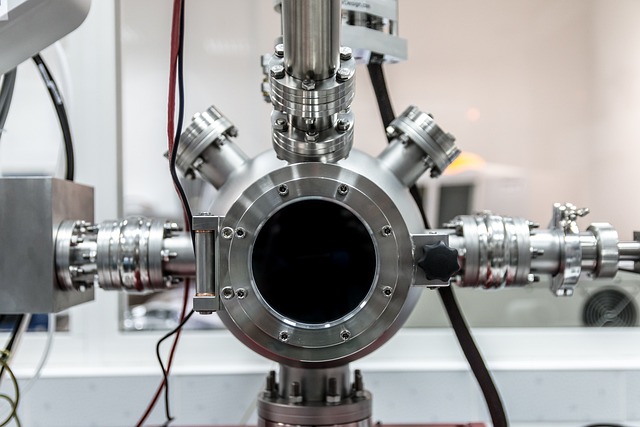

Hot water cylinders are essential components of any home’s plumbing system, and they can present several common issues that require attention. Understanding these problems is the first step in effective hot water cylinder repair. One of the most noticeable signs is a significant drop in water pressure, which could indicate a faulty valve, mineral buildup, or even air trapped within the system. Fixing hot water pressure issues is crucial to ensure consistent and adequate hot water flow throughout your home.

Another frequent concern is the failure or malfunction of heating elements, especially in electric hot water cylinders. Over time, these elements can degrade, leading to insufficient heating or even complete cessation of hot water production. A DIY hot water cylinder repair tutorial might be useful for those inclined to tackle such tasks themselves. However, repairing an electric hot water cylinder requires careful assessment and specific knowledge to ensure safety and effectiveness.

Check for Leaks and Corrosion

One of the most common issues with hot water cylinders is leaks and corrosion. Regularly inspect your hot water system for any signs of moisture or dripping around connections, valves, and pipes. Leaks can indicate worn-out seals, loose connections, or damaged valves, all of which require attention from a professional to ensure proper hot water cylinder repair. Corrosion, on the other hand, is a silent but potent threat that can weaken the integrity of your cylinder over time. Look for orange or blue stains on the tank’s surface, which are classic indicators of corrosion. If left unattended, it can lead to serious structural damage and even pose safety hazards.

Addressing these issues early on is crucial, whether you’re dealing with a fixing a hot water heater that won’t heat up or simply trying to extend the life of your existing system. The best time to call for hot water cylinder repair is during scheduled maintenance checks when any potential problems can be identified and fixed promptly. For electric hot water cylinders, repairing an issue as soon as it’s noticed could save you from more costly replacements in the future.

Evaluate Heater Element Performance

When diagnosing hot water cylinder problems, evaluating the heater element’s performance is crucial for identifying potential issues. Start by checking if the element is functioning properly and heating the water as expected. You can do this by observing the cylinder’s temperature output during usage. If the water temperature is consistently low or uneven heating occurs, it may indicate a faulty heater element. This is one of the most common hot water cylinder repair scenarios that homeowners often encounter.

Identifying specific hot water cylinder parts and understanding their functions is vital for effective troubleshooting. Referring to user manuals or seeking hot water cylinder parts identification guides can help you locate and assess the condition of individual components, including the heater element. Additionally, considering hot water cylinder troubleshooting tips from reputable sources can empower you to take on basic repairs yourself. However, for more complex issues, it’s recommended to hire a licensed hot water cylinder technician who can accurately diagnose and resolve the problem while ensuring safety and optimal performance.

Assess Temperature Control Mechanisms

When diagnosing hot water cylinder problems, assessing the temperature control mechanisms is a crucial step in hot water cylinder repair. Start by checking the thermostat to ensure it’s functioning correctly and setting the desired temperature. If your cylinder uses an electric heating element, verify that power is reaching the element by testing the circuit breaker or fuse. In gas-powered cylinders, inspect the pilot light for any signs of flame failure or leaks.

Regular maintenance can prevent many issues, so keep an eye on unusual noises coming from the cylinder, such as banging or bubbling sounds, which might indicate problems with pressure buildup. If you notice a persistent leak, it’s time to consider how to fix a leaky hot water cylinder. You may decide to order replacement hot water cylinder online if the damage is severe or if repairing an electric hot water cylinder proves challenging.

Inspect Insulation and Storage Tank Condition

When diagnosing hot water cylinder problems, one of the first steps is to thoroughly inspect the insulation and storage tank condition. Over time, thermal insulation can degrade, leading to heat loss and reduced water heating efficiency. Check for any signs of damage, corrosion, or mold growth inside the tank. These issues not only affect performance but also pose safety hazards. Regularly inspecting and maintaining the insulation is a crucial aspect of hot water cylinder repair and can help prevent more serious problems down the line.

Additionally, listen for unusual noises coming from the heater, such as banging or rumbling sounds, which could indicate a faulty dip tube or sediment buildup. If you’ve noticed a decrease in water pressure, it might be time to consider replacing the hot water filter to improve pressure. Similarly, if your hot water valve is clogged, fixing it promptly can restore efficient water flow and temperature control, addressing issues like slow heating times and inconsistent temperatures.

Diagnosing hot water cylinder problems is a multi-step process involving careful inspection of various components. By identifying common issues such as leaks, corrosion, heater element malfunction, and temperature control anomalies, you can effectively assess the health of your hot water cylinder. Additionally, examining the insulation and storage tank condition ensures optimal performance and longevity. Armed with this knowledge, you’re better equipped to address problems promptly or consult professionals for specialized hot water cylinder repair solutions.